Fighting the Epidemic | There is a clever way to treat industrial waste liquid, Fusheng HD system can help you save processing costs

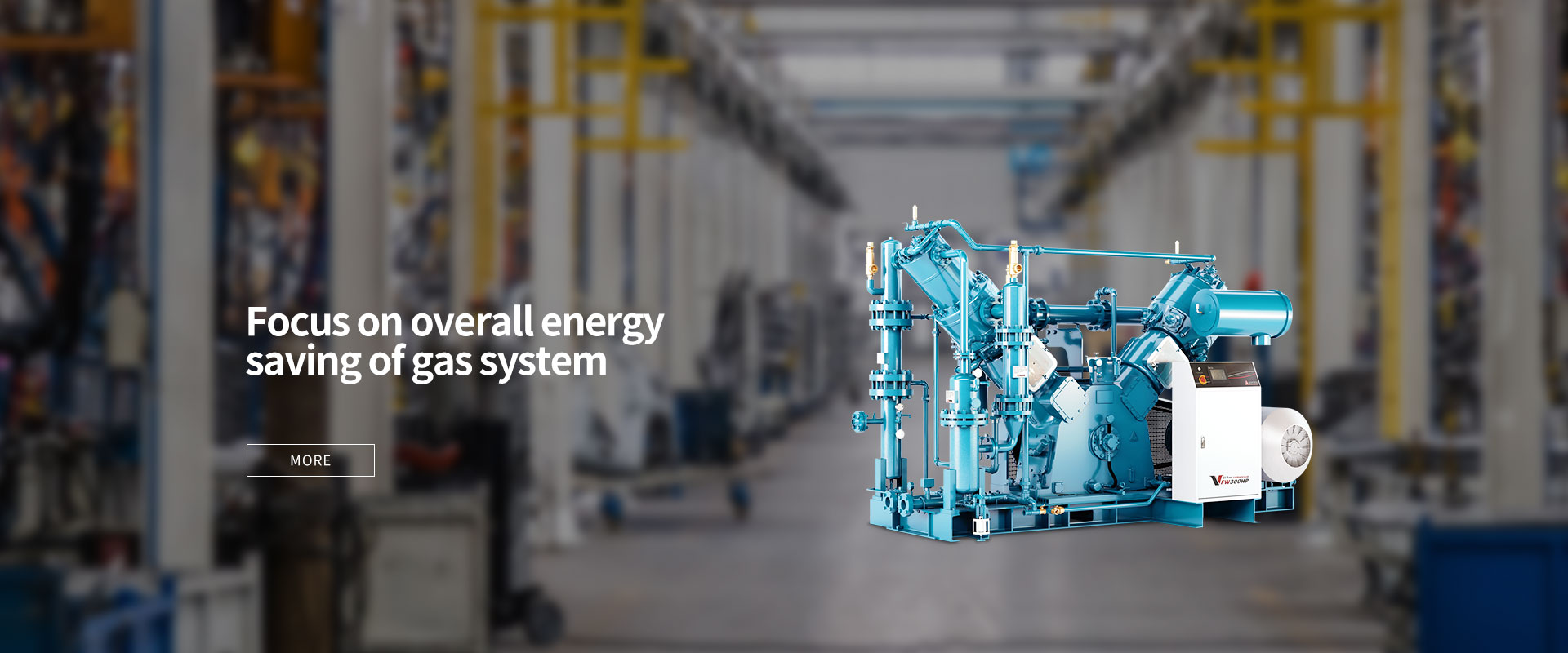

At present, the environmental damage caused by the waste water and liquid produced in the industrial production process, and the reduction of waste water treatment costs and the recycling of water resources have become important environmental protection issues faced by the industry. Fusheng Company adopted its own refrigerant compressor products, combined with the condensation application of refrigerant compressors, and successfully developed the HD industrial waste liquid reduction system with low energy consumption.

With the complex composition of various wastewaters, the treatment methods of industrial wastewater are changeable, and the existing technology has been unable to effectively overcome them. Taking industrial metal cutting waste liquid treatment as an example, metal cutting liquid is a waste liquid with high concentration of chemical oxygen demand (COD). The coagulation method will also bring a large amount of sludge waste, and the treatment effect is limited. In particular, most of the wastewater has the characteristics of being difficult to decompose by biology, and it will emit carbon and energy through incineration. In the face of strict environmental protection regulations, only by reducing the amount of waste, properly treating it for recycling and reusing it can reduce the impact on nature. Pollution, reduce the processing cost of the industry, take into account environmental protection and economy.

The HD industrial waste liquid reduction system has the characteristics of low carbon, energy saving, environmental protection and economy. It can be used in the reduction of waste cutting fluid, as well as in printing and dyeing wastewater treatment, electroplating wastewater treatment, salt wastewater treatment, power plant wastewater treatment, chemical plant In industrial fields such as wastewater treatment, refining wastewater treatment, coking wastewater treatment, and traditional Chinese medicine concentration treatment, it can effectively increase the energy of environmental protection treatment and make obvious contributions to the improvement of green processes.

Fusheng Company follows the ISO14001 and ISO50001 management systems. The R&D team uses its own new condensation technology for refrigerant compression applications to formulate an improvement plan for metal cutting fluid reduction. The developed HD industrial waste fluid reduction system occupies a small area and adopts The high-speed scroll compressor achieves a low-energy-consumption condensation operation mode and reduces operating costs. Through the R134a environmentally friendly heat pipe heating design, the water quality is fully discharged and stable, and recycled to the front-end system for repeated use. The goal is to achieve zero emissions. One of the solutions for green process.

According to Fusheng's own experience, the Sanzhong plant needs to eliminate about 300 tons of processing cutting fluid every year (the ratio of waste/water is about 1:20). tons of waste liquid that needs to be outsourced. At present, the cost of processing waste liquid outsourced to environmental protection companies is 4 yuan/kg, and the treatment cost of 15 tons of waste liquid is 60,000 yuan, plus the electricity cost of system operation is 80,000 yuan, and the consumption of consumables is 40,000 yuan. As a result, the cost of waste liquid treatment in the Sanzhong plant has plummeted to 180,000 yuan. Compared with no treatment, if the 300 tons of waste liquid generated is entrusted to the environmental protection industry, it will generate a treatment cost of 1.2 million yuan per year. The HD industrial waste liquid treatment system helps the company save nearly 1.02 million yuan in treatment costs.

Fusheng provides customized industrial waste liquid treatment solutions for different customer situations. In this special situation, Fusheng hopes to provide enterprises with more new ideas for energy saving, minimize the impact of the new crown epidemic, and work with everyone to tide over the difficulties, and at the same time, to win the "Blue Sky Defense War" "Lay the groundwork.

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!