- SA Classic Series Micro Oil Screw Air Co...

- SA+ two-stage compression series screw a...

- SWV series oil-free screw air compressor

- SWT series oil-free screw air compressor

- P series centrifugal air compressor

- GTS series centrifugal air compressor

- Piston Reciprocating Air Compressor

- VFW oil-free medium pressure air compres...

- GW series oil-free scroll air compressor

- refrigerant compressor

- Compressed air precision filter

- Compressed air dryer

- Compressed air adsorption dryer

SA+ two-stage compression series screw air compressor

EXHIBTION

Product show

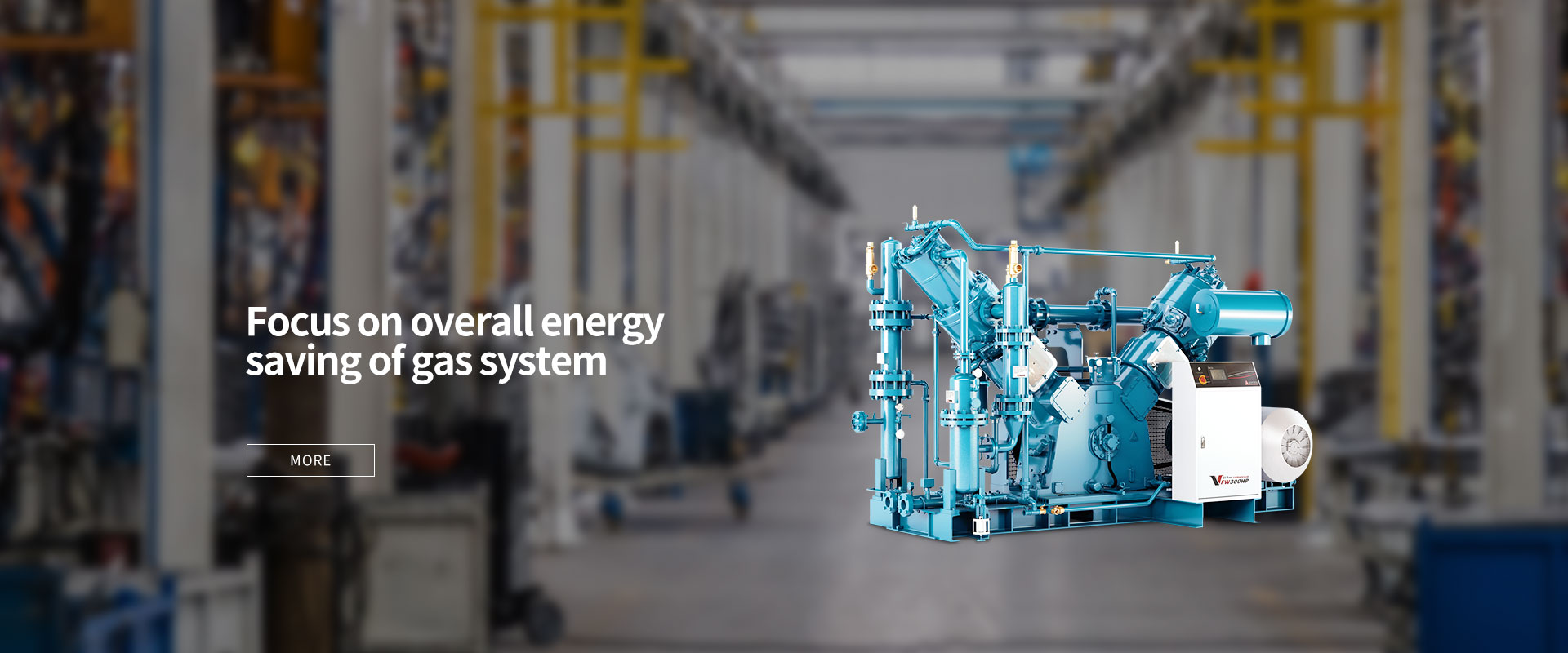

DESCRIPTION

Product Description

SA+ series two-stage compression screw air compressors, screw rotors with advanced patented tooth profile design, equipped with precision-machined one-piece body, become air compressor models with integrated technology. Good efficiency, low energy consumption performance, horsepower from 5.5kW to 400kW, in line with energy efficiency standards. Advanced and considerately designed cooling flow field, precision filtration and degreasing system, and balanced low-vibration, low-noise overall engineering device, easy to maintain and maintain Space planning, intelligent human-machine interface control system, plus computer detection and self-diagnosis and other security protections It is designed to become a dedicated screw air compressor for industrial grades in the market, driving various industrial applications. Two-stage compression compression screw air compressor, because the high-temperature air after single-stage compression is cooled by oil injection, the air is isobarically compressed, thereby reducing the double-stage suction temperature, and the entire compression process is close to isothermal compression, reducing compression power consumption . The pressure ratio of each stage of the double-stage compression is reduced, so the leakage of the seal between the rotors is greatly reduced, and the volumetric efficiency of the head is improved; compared with the single-stage compression of the same power air compressor, the double-stage compression can theoretically increase the displacement by up to 8~15% , correspondingly saving 8~15% of energy consumption. When running at full load for a long time, the CP value is good. In our practical case, combined with comprehensive centralized control, frequency conversion, elimination of unreasonable use and other comprehensive measures, the new compressed air system can save up to 40% of electricity costs compared to the original system. In addition to energy saving, double-stage compression also has the characteristics of stability and reliability. The working pressure is achieved through two-stage compression. The pressure ratio of each stage is small, which means that the pressure difference between the intake and exhaust of each stage of the rotor is small, the main components are under small stress, and the thermal load is low. . At the same time, it can also reduce the load of the bearing, prolong the service life of the main engine, and ensure the reliable operation of the whole machine.

ADVANTAGE

Product advantages

-

Two-stage compression compression screw air compressor

SA+ series two-stage compression screw air compressors, screw rotors with advanced patented tooth profile design, equipped with precision-machined one-piece body, become air compressor models with integrated technology.

-

Good efficiency and low energy consumption

Advanced and considerately designed cooling flow field, precise filtration and degreasing system, and balanced low-vibration, low-noise overall engineering device, easy to maintain and maintain Space planning, intelligent human-machine interface control system, plus computer detection and self-diagnosis and other security protections It is designed to become a dedicated screw air compressor for industrial grades in the market, driving various industrial applications.

-

Stable and reliable features

Two-stage compression compression screw air compressor, because the high-temperature air after single-stage compression is cooled by oil injection, the air is isobarically compressed, thereby reducing the double-stage suction temperature, and the entire compression process is close to isothermal compression, reducing compression power consumption . The pressure ratio of each stage of the double-stage compression is reduced, so the leakage of the seal between the rotors is greatly reduced, and the volumetric efficiency of the head is improved; compared with the single-stage compression of the same power air compressor, the double-stage compression can theoretically increase the displacement by up to 8~15% , correspondingly saving 8~15% of energy consumption. When running at full load for a long time, the CP value is good.

SPECIFICATION SELECTION

Specification selection

SA+04-11

|

model |

Exhaust volume(m3/min) |

(Mpa) |

rated power(kW) |

|

SA+04A-7 |

0.60 |

0.7 |

4 |

|

SA+04A-8 |

0.56 |

0.8 |

4 |

|

SA+04A-10 |

0.48 |

1.0 |

4 |

|

SA+04A-12 |

0.40 |

1.25 |

4 |

|

SA+06A-7 |

0.84 |

0.7 |

5.5 |

|

SA+06A-8 |

0.78 |

0.8 |

5.5 |

|

SA+06A-10 |

0.68 |

1.0 |

5.5 |

|

SA+06A-12 |

0.60 |

1.25 |

5.5 |

|

SA+08A-7 |

1.27 |

0.7 |

7.5 |

|

SA+08A-8 |

1.18 |

0.8 |

7.5 |

|

SA+08A-10 |

1.00 |

1.0 |

7.5 |

|

SA+08A-12 |

0.80 |

1.25 |

7.5 |

|

SA+11A-7 |

1.82 |

0.7 |

11 |

|

SA+11A-8 |

1.70 |

0.8 |

11 |

|

SA+11A-10 |

1.55 |

1.0 |

11 |

|

SA+11A-12 |

1.35 |

1.25 |

11 |

|

SA+04A-7P |

0.60 |

0.7 |

4 |

|

SA+04A-8P |

0.56 |

0.8 |

4 |

|

SA+04A-10P |

0.48 |

1.0 |

4 |

|

SA+04A-12P |

0.40 |

1.25 |

4 |

|

SA+06A-7P |

0.84 |

0.7 |

5.5 |

|

SA+06A-8P |

0.78 |

0.8 |

5.5 |

|

SA+06A-10P |

0.68 |

1.0 |

5.5 |

|

SA+06A-12P |

0.60 |

1.25 |

5.5 |

|

SA+08A-7P |

1.27 |

0.7 |

7.5 |

|

SA+08A-8P |

1.18 |

0.8 |

7.5 |

|

SA+08A-10P |

1.00 |

1.0 |

7.5 |

|

SA+08A-12P |

0.80 |

1.25 |

7.5 |

|

SA+11A-7P |

1.82 |

0.7 |

11 |

|

SA+11A-8P |

1.70 |

0.8 |

11 |

|

SA+11A-10P |

1.55 |

1.0 |

11 |

|

SA+11A-12P |

1.35 |

1.25 |

11 |

|

SA+04A-7F |

0.60 |

0.7 |

4 |

|

SA+04A-8F |

0.56 |

0.8 |

4 |

|

SA+04A-10F |

0.48 |

1.0 |

4 |

|

SA+04A-12F |

0.40 |

1.25 |

4 |

|

SA+06A-7F |

0.84 |

0.7 |

5.5 |

|

SA+06A-8F |

0.78 |

0.8 |

5.5 |

|

SA+06A-10F |

0.68 |

1.0 |

5.5 |

|

SA+06A-12F |

0.60 |

1.25 |

5.5 |

|

SA+08A-7F |

1.27 |

0.7 |

7.5 |

|

SA+08A-8F |

1.18 |

0.8 |

7.5 |

|

SA+08A-10F |

1.00 |

1.0 |

7.5 |

|

SA+08A-12F |

0.80 |

1.25 |

7.5 |

|

SA+11A-7F |

1.82 |

0.7 |

11 |

|

SA+11A-8F |

1.70 |

0.8 |

11 |

|

SA+11A-10F |

1.55 |

1.0 |

11 |

|

SA+11A-12F |

1.35 |

1.25 |

11 |

ONLINE INQUIRY

在線詢盤

在線詢盤

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!